“Expectations Were High” – New LB Series in Operation

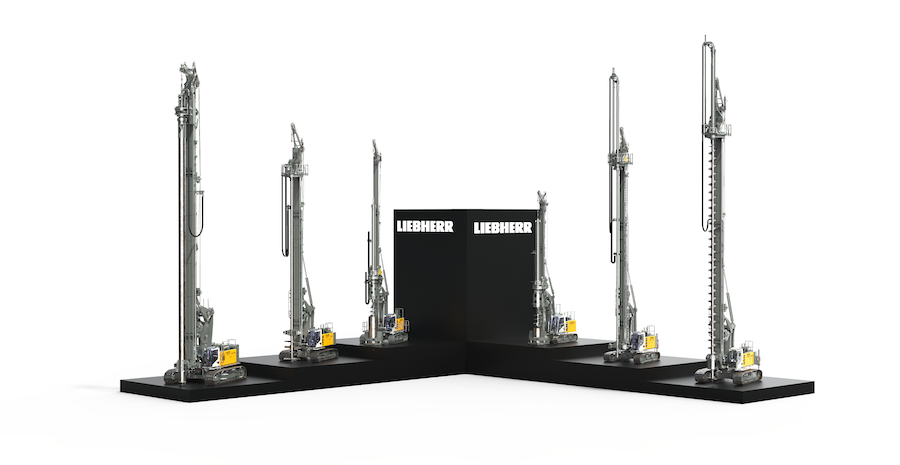

The company Kurt Motz Baubetriebsgesellschaft GmbH in Illertissen (Germany) decided on 5 machines from Liebherr’s brand new series of drilling rigs. Liebherr-Werk Nenzing GmbH recently handed over the key for the LB 45, which is already successfully operating on its first jobsite.

“We have maintained a close partnership for many years,” says Wolfgang Bucher, Leading Site Manager at Kurt Motz. “Suggestions for improvement are discussed constructively and applied quickly. That makes it possible for us to complete complicated construction projects without any problems.” The company has been a customer of Liebherr-Werk Nenzing GmbH since the introduction of the series of drilling rigs and received the very first LRB 125.

Kurt Motz attaches a lot of importance to being on the cutting edge of technology. Therefore, between October 2020 and March 2021, the company is gradually converting to the new LB series from Liebherr with these 5 machines. Recently Christoph Dona, Sales Manager at Liebherr-Werk Nenzing GmbH, was able to hand over the key for the LB 45 to Wolfgang Bucher. One LB 20.1, one LB 25 and two LB 30s will follow.

Even more flexibility

A decisive factor for exchanging the machines was the huge advantages in flexibility. The modular leader can be easily converted from the standard to a low head version. Remote control facilitates safe loading and unloading of the machine on or from the low loader, or assists during assembly. Machine operator Anestis Papanikolaou adds, “The new assistance systems such as Kelly Visualization and Ground Pressure Indication make life a lot easier. You can feel the 10 % more power of the LB 45 over its predecessor immediately.” Thomas Markus, Workshop Manager at Kurt Motz, also emphasizes the good customer service with excellent advice and fast parts deliveries.

Features for higher safety and easier operation

The ground load-bearing capacity and the monitoring of the ground pressure are decisive for the safe operation of a machine. The Ground Pressure Visualization of the LB 45 calculates the current ground pressure of the machine in real time and compares it with the specified safety limits of the relevant jobsite. The ground pressure is displayed in the operator’s cab and the operator is permanently aware of whether the machine is situated in, or is approaching, a critical area. Dangerous work stages can so be avoided or adapted in good time.

Locking of the Kelly bar’s telescopic sections is made significantly easier due to the Kelly Visualization system in the LB 45. Thanks to the real time display of the Kelly bar’s locking recesses on the cabin monitor, the operator is permanently informed of the actual distance to the next locking recess. Colour indications inform when the bar can be locked. Furthermore, false positioning of the Kelly bar during the shake-off process is indicated through a warning signal. All assistance systems contribute to time savings, higher availability of the machine and a significant increase in safety during operation.

First deployment

The LB 45 celebrated its premiere directly with Liebherr. A fully automated high-bay warehouse is being built at the works in Ehingen and Kurt Motz was awarded the contract for the foundation piles. Approximately 450 piles, equivalent to about 9,000 drilling metres, will be installed by the brand new LB 45 together with the drilling rig LB 28 using the Kelly drilling method.

Machine operator Anestis Papanikolaou gives an encouraging feedback, “The expectations of the LB 45 were high, but they have been fulfilled 100 %.”