| EK160 | LB 44-510 | BG 28 H |

|---|---|---|

| CZM Foundation Equipment | Liebherr | Equipment Corporation of America (ECA) |

| More information | More information | More information |

|

|

|

Pile Buck's Top Recommended Rigs

| TD100 | BG 23 | Tescar TT5 |

|---|---|---|

| TEI Rock Drills | BAUER Equipment America | Western Equipment Solutions |

| More information | More information | More information |

|

|

|

| Patriot P1 |

|---|

| Ring Power |

| More information |

|

What is foundation drilling?

Foundation drilling is, in essence, using big machines to put big holes in the ground.

Most residential homes have a reinforced, concrete slab foundation poured on top of the ground. Though some settling and shifting will occur, it is not enough to send the walls tumbling down. However, huge structures like bridges and office buildings, need foundations that can handle some movement and are strong enough to carry the weight of the building itself and what’s on or inside of it. To do this, large construction projects use foundation drilling rigs to create drilled shafts. Also known as drilled piers, caissons or bored piles, drilled shafts are constructed by pouring concrete into a drilled hole. The load is supported mainly through skin friction where the subsurface soil surrounding the shaft holds it in place. End-bearing shafts carry the weight load on the base of the shaft. This type of drilled shaft is used less often.

The type of rig used depends on several factors. How deep and what the diameter of the holes will be, obviously. But, the type of soil, where the project is located (in a city or out in the boonies), and how much room there is to maneuver are just some of the considerations. The project requirements will also dictate which foundation drilling method is used.

These are the most common drilling methods:

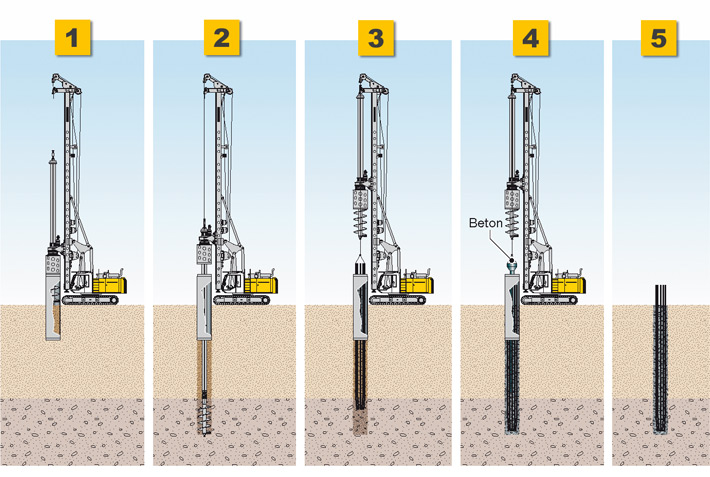

Kelly Drilling

Kelly drilling is a dry rotary drilling method. It is used to make bored piles with a large diameter, typically over 500mm. It’s is popular because it works for most types of rock and soil. A key part of this method is the telescopic drill rod – also known as the Kelly bar.

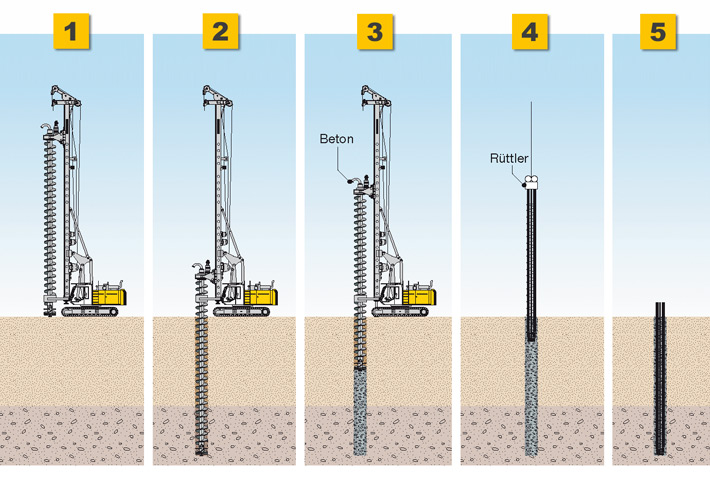

Continuous Flight Auger Drilling

Continuous flight auger drilling is another dry rotary method. It uses rotation of a continuous flight auger to displace soil. The auger needs to be the same length as the hole that will be drilled. This makes it a good solution for predrilling.

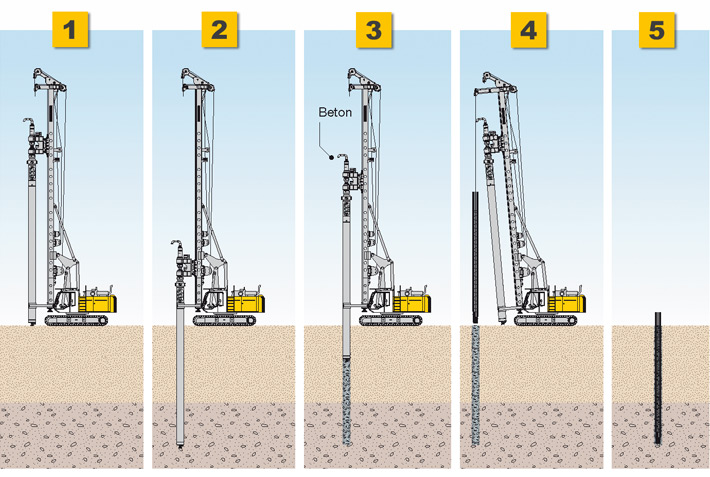

Double Rotary Drilling

Double rotary drilling combines continuous flight auger drilling with a continuous casing. This method is used for challenging soil conditions or sensitive environments. Drill cuttings are ejected from an opening in the top of the auger.

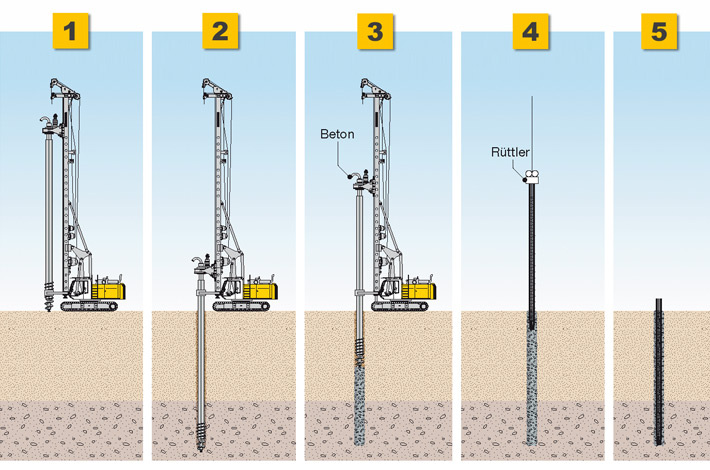

Full Displacement Drilling

Full displacement drilling is used for cast-in-place piles. The surrounding soil is only displaced and virtually no drill cuttings are brought to the surface. A smooth casing is used and fitted with a displacement body at the lower end.

Grab Drilling

Grab drilling is the oldest of the dry drilling methods. Soil is loosened by cutting or impact driving. This method is typically used for well drilling or cast-in-place piles.

Reverse Circulation Drilling

Reverse circulation drilling can produce boreholes of about 3.2m diameter. The method is useful in challenging soil conditions such as karst. This method uses the mammoth pump principle. The flushing drill fluid rises inside the drill rod and brings the drill cuttings to the surface. This technique can be used for soil or rock drilling.

Down-the-Hole Drilling

For very hard rock or to break up boulders, the down-the-hole drilling method is used. A hammer is mounted on the drill bit at the end of the drill rod. Compressed air is used to pneumatically break and remove the rock or boulders. The bit breaks up the rock by rotating and impacting at the same time. The compressed air moves the loosened drill cuttings to the surface.

No matter the method, there is a foundation drilling rig available to put those big holes in the ground, in the right place, at the right depth.

Kelly Drilling

CFA Drilling

Double Rotary Drilling

Full Displacement Drilling

How to Select Foundation Drilling Rig

Selecting the right foundation drilling rig can be daunting. They’re expensive – so you want to get it right the first time. You want to drill down (pardon the pun) to what your requirements truly are. Once you understand your “must-have” (hard) requirements, you can find the foundation drilling rig to meet them. There is no one-size-fits-all drill that works for all types of drilling and all site conditions.

Job Description

You want to determine the specifics of the job you need to get done. The diameter and depths of the holes, the type of soil, and the features of the site must be known.

Location Challenges

Are you working on rough terrain? Is the job in the heart of a city where noise reduction is critical? Is it a small lot or other tight space that will require smaller, more nimble equipment? The rig you choose must be able to work within the limitations of the job site.

Mobility

An autonomous crawler drilling rig does not need additional equipment or a separate power source to move around the job site. Truck-mounted and trailer-mounted foundation drilling rigs need to be powered by a generator or by the truck that’s moving them about.

Stability

An important part of any foundation drilling rig is the stability of the platform. The amount of ground pressure the rig exerts matters. It impacts how large the platform must be. So, the size of the construction site can limit the weight of the rig you can buy. The manufacturer will tell you how much pressure their rig exerts. Lighter weight models, such as Commachio’s MC 3, can provide plenty of power and still squeeze through areas as narrow as 9mm.

The rig should be placed on level and firm ground. The area must graded to support the rig per the manufacturer’s specifications. Crane mats can be used to support the platform. They are typically made from 12″ thick timbers and are available in lengths from 8- to 40-feet. Widths of 4, 5, or 6 feet are available. The Crane Mat Company also offers custom mats and used mats that have been returned through their buyback program. You can also rent crane mats. Bridgewell makes all-steel Mammoth Mats for multi-million pound rigs.

On Special Occasions

Some jobs require custom features that you won’t be able to use for other projects. If possible, select a standard foundation drilling rig and add attachments that will meet the requirements of a particular job. You want the rig you select to have the broadest use possible.

Cutting Technology or Old School?

Fancy color screens, automatic placement, and torque technology are terrific. But you may not need them to complete a project. The training required to use the features of high-tech equipment also adds to the project timeline and budget. Sometimes a foundation drilling rig that is less high-tech with a longer track record is a lower-risk – and lower cost – solution.

Price

It is natural to think of price first. But, resist the urge. Figure out what your requirements are for the job. You should have two lists – hard requirements and “soft” requirements. (Soft requirements are nice-to-have features that are not necessary to get the work done.) Present this information to at least three vendors and let them advise which foundation drilling rigs are best based on these requirements. Considerations can also be made for ongoing maintenance costs, reliability as well as flexibility.

Wrap Up

The most important aspect of selecting a foundation drilling rig is understanding what you really need to get the job done. Take the time to meet with a sales engineer and other experts to clearly define the project requirements. Find a few models that will meet your needs then shop around.

Soilmec SR-45

Woltman 160 DR

Liebherr LB 28-320

Tips for Inspecting a Foundation Drilling Rig

Inspecting your foundation drilling rig is critical for job safety. In addition to keeping workers and the public safe, you want to protect your investment. The rig should be inspected prior to using it – every time. You will be checking parts of the rig big and small. This includes braking systems, Kelly bars, hydraulic systems, wire ropes, safety features, and anything else recommended in the manufacturer’s documentation.

Qualified Inspector

This may seem obvious, but you really need someone experienced in inspecting drilling rigs to do the inspection. A checklist is helpful. Some jobs require documentation to be filed as proof that the inspection was completed. In any case, an inspection logbook should be kept inside the rig.

Brakes

Check for wear and tear to the brakes. Ensure brake fluid levels are adequate. Wheel-mounted rigs have three braking systems: Service, secondary, and parking. The parking braking system should be able to keep the rig stationary on the steepest slope it is built to operate on.

Kelly Bars

Kelly bars should be inspected outside of their housing. Adapters, flanges, stops, torque lugs or rails should not be worn out or damaged. Check the torque of the Kelly retainer clamp bolts. Also inspect them for wear and tear.

Hydraulic Systems

Wear gloves and use a piece of cardboard or wood to check for leaks in the hydraulic system. Check the hydraulic level indicators.

Lubrication

Grease is the lifeblood of the foundation drilling rig. Before greasing lubrication points, first clean out the dirt and old grease.

Warning Devices

Make sure the warning signal (audible and or visual) automatically functions when the rig is in reverse. Any warning signs should be clearly visible. Warning devices are not always a replacement of a spotter when moving the rigs.

Wire Ropes

Wire ropes should be reeved properly on the sheave and in good condition. Inspect for kinking or unstranding, corrosion, heat damage, etc.

Manufacturer’s Manuals

Detailed manuals from the manufacturer should be stored in the rig so they are readily available when needed. Complete the specific inspections recommended by the manufacturer.

Clean Up

Inspections are more often successful when regular maintenance is done on your foundation drilling rig. The most important maintenance involves keeping the parts of the rig clean. Keep your inspection records up-to-date and ensure any needed repairs are completed before the rig is used on the job.

CZM EK200SM

Bay Shore TR40

What Should a Foundation Drilling Rig Cost?

All that power doesn’t come cheap. But the right foundation drilling rig gets the job done faster and more accurately – saving money and headaches down the road. Part of the cost is the amount of automation offered. For example, the Liebherr LRB-355 has a crane control system with a color display. Its hydraulic BAT rotary drive provides automatic torque adjustment.

Soilmec’s innovative SR-125 in the Kelly configuration costs about $2,200,000, depending on the type of Kelly bar you choose.

Other cost factors include how quickly the rig can be assembled and how nimble it is. Noise reduction features can up the price.

CZM’s EK200LS Cased CFA may fit the bill. These state-of-the-art rigs are estimated at $1,750,000. CFA is also used for residential projects, such as building a home on the California coastline.

Foundation Drilling Rigs for Tight Spaces

There are several scenarios where your equipment just won’t have a lot of swinging room. Bay Shore System’s LAD Series may be the right solution. Their small foundation drilling rigs have attachment heights down to 6 feet 6 inches. Yet, they can drill down to 70 feet. They also have a wide torque range to handle tough soil.

Used Foundation Drilling Rigs

Another option is to buy a used foundation drilling rig. Of course, there’s risk involved, but the savings are huge. For example, a 2007 AD 150 Crawler Drill is currently listed with an asking price of $200K. Of course, finding attachments and spare parts is always a challenge with an older rig. Just like used cars, however, you can buy higher quality used foundation drilling rigs from reputable dealers. You should also consider whether a company provides service in your local area. This could make it easier to find parts.

Innovative Designs

There are some interesting and innovative foundation drilling rig designs. Watson’s 4300 has a top-applied Kelly crowd system that eliminates the need for a rotary / bar locking system. Their claim is that wear and tear on the rotary from crowd forces is eliminated and that the rig drills straighter holes. All at a cost of about $1,200,000.

Research First, Price Later

Don’t select your foundation drilling rig on price alone. In fact, don’t consider price at all when you start your research. Gather your hard requirements and optional requirements and let vendors tell you what rigs will meet them. Then put it out for bid. Ask if there is a “certified used” option available. You may do better buying a stripped-down model and purchasing the attachments you need for the job. Spend the time to educate yourself on the right drilling method for the job. Then identify any restraints, such as noise level and height restrictions, before you start shopping for foundation drilling rigs. Knowledge is power and savings.

Bauer BG 15 H

Junttan MPx50

Foundation Drilling Rig Tooling & Attachments

There are many different types of foundation drilling rig attachments to meet any job. Here are some popular attachments from top vendors.

Champion Equipment fabricates various styles of drilling buckets, one being the pitched bottom bucket. The bucket bottom is heat pressed into its unique shape which allows for larger openings and smoother material flow into the bucket. These buckets are sold in diameters from 1 foot to in excess of 16 foot and can be equipped with both manual and automatic dumping systems.

Jeffrey Machine specializes in augers they call laminates. Their augers are available in diameters from 6-inches to over 12-feet. Jeffrey Machine has a state-of-the-art manufacturing facility in Alabama. They claim a huge inventory of off-the-shelf products. But, they can custom build drilling tools using customer or JMI prints. They may even be able to get your specs over the phone.

Bay Shore Systems’ LoDril® drilling attachment has 360 degrees of operating area. It can reach up to 15 feet beyond the tracks or above casing. Perfect for foundation drilling in challenging environments like tight areas or sloping terrain. There are six sizes available, starting at just seven feet high.

Numa designs and manufactures rock drilling hammers and bits for vertical and horizontal applications. Their U.S. made Down-the-Hole and HDD hammers and bits can drill holes from 3.5 inches to 50.5 inches (89mm-1283mm). Built specifically for longevity and penetration rate, Numa’s rock drilling equipment drills at high frequency and require less air. Even against high heads of water.

TEI manufactures a lightweight drill attachment for 5- to 8-ton mini excavators that’s a good solution for limited access areas. The standard version has one 360-degree positioner and a single hydraulic clamp on the drill feed. It includes radio remote controls with a manual override. You can add a second 360-degree positioner for unlimited positioning capabilities.

Armador offers many foundation drilling rig attachments. Their core barrels are made of special steel alloys. They claim that their welding techniques increase the life cycle of the product. They have off-the-shelf standard core barrels, but offer customized versions including kelly boxes in any size or shape to conform to your drilling rig. Armador’s standard core barrel models are KOS Series (round shank picks) and the KOB Series (weld-on bars core barrel with trap).

Most of these vendors can manufacture custom or semi-custom foundation drilling rig attachments. Some offer used inventory. The array of choices can be dizzying. Work with the vendors to understand what attachments are really needed for your foundation drilling rig.

Champion Equipment Attachment

Jeffrey Machine Attachment

PILE BUCK’S TOP RECOMMENDED FOUNDATION DRILLING RIGS

Description

The EK160 is engineered in response to customer demands for a machine with the power of a larger model and the ease of greater mobility- it can be transported in one load. It is available in standard and short masts and has transport weights of 100,000lbs/91,000lbs with the Kelly bar. Built on a CAT 330F base with an installed 242 horsepower, the EK160 delivers an impressive maximum effective torque force of 151,100lbs. It has all set up functions inside the cabin and it can be drilling minutes after unloading from the truck. It also has automatic operator assistance features, like mast auto level, return to center, high spin off, auto gear shifting for rotary and main winch, drill lock and telematics. This machine has excellent stability due to hydraulic extendable crawlers, additional counterweight and a mast manufactured in “Weldox” steel (light weight – high yield strength) and has a max drilling diameter of 11ft.

Technical Specs

Standard chassis: CAT330 Next Gen

Application: Kelly Bar

Installed power: 275 hp

Maximum nominal torque: 134,300 lbf.ft

Main winch nominal pull line: 41,000 lbf

Crowd force: 44,200 lbf

Maximum depth: 120 ft

Maximum diameter: 10 ft

Minimum transport weight (w/ Kelly 4/120 ft): 105,000 lb

CZM Foundation Equipment

Description

The SR-125 is one of the newest rigs in the large diameter piling category. Part of the High Technology Line, whose main driver is the multifunctionality, SR-125 has been designed for bored piles with kelly bar and CFA, but can be easily converted to perform the majority of piling and soil consolidation techniques, to improve productivity and operating flexibility to higher degrees.

The SR-125 is fitted with the latest masts and rotaries from Soilmec, reducing overall weight, while adding increased strength, torque, and pull-up capacity. SR-125 is a major upgrade compared to previous generations. The H-cab has been designed to offer the operator maximum comfort and the complete control and monitoring over the rig and technological parameters with the DMS 12” touchscreen. Like all Soilmec rigs, the SR-125 is self-assembling, versatile, and easily transportable.

Technical Specs

Weight: 281,310 lb

Power: 630 hp

Torque: 303,133 lb-ft

Extraction: 121,395 lbf

Max diam.: 138 in (or 157 with special kit)

Max depth: 395 ft

DMS: 12” standard (DMS PC and Manager 4.0 available)

Soilmec North America

Description

The LB 44-510 drilling rig is the most powerful representative of the well-known LB series from Liebherr. Besides the common Kelly drilling other methods like continuous flight auger drilling, drilling with full displacement tools or double rotary drilling can be applied. The heavy-duty machine with an enormous torque of 510 kNm is very compact in design which guarantees a cost effective transportation and fast mobilization on site. The rig is equipped with a powerful diesel engine which convinces through low consumption and reduced emissions. In combination with the board hydraulics and the operator-friendly rotary drive the LB 44-510 is designed for continuous operation and very fast drilling cycles.

Technical Specs

Operating weight: 155.0 t

Max. torque: 510 kNm

Max. winch line pull: 500 kN

Max. crowd force: 560 kN

Engine power: 505 kW

Kelly drilling, max. drilling depth: 94.2 m

Kelly drilling, max. drilling diameter: 3,000 mm

Continuous flight auger drilling, max. drilling depth: 30.0 m

Continuous flight auger drilling, max. drilling diameter: 1,400 mm

Full displacement drilling, max. drilling depth: 30.0 m

Full displacement drilling, max. drilling diameter: 600 mm

Double rotary drilling, max. drilling depth: 23.0 m

Double rotary drilling, max. drilling diameter: 900 mm

Min. transport width: 3,480 mm

Min. transport height: 3,390 mm

Liebherr USA Co. MCCtec Division Crawler Cranes and Foundation Equipment

Description

The BAUER BG 28 H has traditionally been one of the best sellers in the BG lineup. Like all PremiumLine rigs, it is capable of a wide range of applications including Kelly drilling, CFA, FDP, Front of Wall (FoW), CCFA, Single Column Mixing (SCM), Vibro Displacement (VD), Low Headroom, and jet grouting with its ability to accommodate various tools and attachments. The BG 28 H features BAUER’s award-winning B-Tronic System – a one-of-a-kind feature that allows the operator to view parameters including torque, pump pressure, and drilling depths in even the most challenging operating conditions. It also includes several driller assistance systems like Kelly Visualization, which displays the locking recesses resulting in increased drilling performance and significantly reduced wear on the Kelly bar and drive keys. The environmentally friendly Energy Efficient Power (EEP) system reduces fuel consumption by up to 30 percent while noticeably reducing drilling noise levels. The remote control of the BG 28 H enables fast unloading and rigging; and like all BAUER H-Model rigs, the kinematics enable the quick change of working positions to accommodate tramming under low clearance areas.

Technical Specs

Drilling Diameter: 2,500 mm

Drilling Depth: 65.7 m

Torque: 277 kNm

Engine Power: 354 kW

Height: 24.9 m

Equipment Corporation of America

Description

The LōDril is a versatile, powerful excavator-mounted foundation drill for traditional and extreme jobs. Its telescoping kelly bars allow you to drill to depths of 90 feet (27 meters) under severe overhead restrictions with a very low profile attachment—even in the most unfriendly conditions.

We’ll build your LōDril to the specific requirements of your job—but it’ll take you far beyond that. 99 percent of LōDrils are still in use today, including the first one we rolled out in 1991! Whether you purchase a new excavator or mount it on an existing one in your fleet, your LōDril will be engineered for the base machine that makes the most sense for you.

Technical Specs

Rotary torque (max): 15,000 ft-lbs

Kelly winch line pull (first layer, max): 8,000 lbs

Hole diameter: 36 in

Drill speed range (LHS): 30/60/100 rpm

Hole depth (max: 80 ft

Attachment height: 9-21 ft

Excavator weight class x 1000: 16-35 lbs

Bay Shore Systems

Description

TEI Rock Drills is an industry leader in the manufacture of rock drill excavator attachments, limited access drill rigs, safety equipment, and associated components. All TEI products are created by in-house engineers, uniquely patented, and manufactured in our ISO Certified facility. TEI equipment is proudly made in the US with American made parts to ensure quality, efficiency, and up-to-the-minute innovation.

TEI Rock Drills

Description

State-of-the-art German engineering since 1790 combined with energy-efficient power (EEP): meet the BAUER BG 23. Designed to meet your specific needs for multiple applications – from Kelly drilling to SCM – this versatile rig is part of the field-tested BAUER BG-GB line, which is delivering quality and performance on the most challenging jobsites all around the world. If you are looking for the highest safety standards, environmentally-conscious efficiency, and lasting reliability, the BG 23 is the solution that you can count on.

BAUER Equipment America

Description

As everyone knows by now, the acronym “TT” (Tescar Technology) identifies Tescar’s full-optional models, and the TT5 is the top-of-the-line version of the already famous CF4. It is in fact a machine with a special double-motor rotary for 50 kNm of torque with TSP device (torque-speed potentiometer) that permits the operator to progressively set the torque and speed accordingly to the ground conditions. It’s then provided with the special CCMS device (crowd crain motor system) with 8 t capacity, and a sectional mast for working outdoors with 28m kelly bar or in low-headroom version (under 6m height) with 15m kelly bar. The TT5 is mounted on Eurocomach ESP100 UR4 excavator base with EU Stage5 / US Tier4 Final certified Yanmar engine, equipped with heavy duty undercarriage with expanding tracks and hydraulic blade as standard.

Thanks to the chain push/pull, the TT5 boasts a rotary stroke of 5m, which can be extended up to 7m, allowing easy use of the casing pipes by working with longer tools so as to increase and speed up production on site. Thanks to the modularity of the mast, the TT5 can reach 10m depth in the CFA version (6m augers + 4m kelly extension) and 12m in the “CFA Extended” version (8m augers + 4m kelly extension).

The TT5 can then also be equipped in D-WALL mode, with hydraulic grab for diaphragms up to 2000x400mm. This configuration is offered either with a square locking rod and pushing device, or with the original round kelly bar of the LDP version, thus allowing the customer to save a big bunch of money and a lot of time when switching from LDP to D-WALL mode.

As all our other piling rigs, also the TT5 can close on itself and fold the mast backwards for transport, keeping a perfect balance during the loading/unloading operations and leaving space behind the base to eventually stow a skid-loader, the drilling tools and the other necessary working equipment, maintaining an on-size shape and a limited overall weight.

Western Equipment Solutions

Description

The Comacchio CH 450 is designed to cover a wide range of applications including cased or uncased bored piles, continuous flight auger (CFA), micropiles, displacement piles an soil mixing. The machine is completely self-erecting, and can be transported in one load with the Kelly bar mounted. Once in place, the machine is easily offloaded from the truck, and set up for operation does not require a crane. The CH 450 can be supplied in CPD (cylinder pulldown) WPD (winch pulldown) and LHR (low head room) versions. This rig is the winning solution for job sites that require quick operation and minimal transportation costs.

Technical Specs

Mast height (LHR): 30’

mast height (WPD): 65’ 3”

Stroke (WPD): 47’ 6”

Operating weight (WPD): 98,800 lbs

Max pile depth (WPD): 165’

Max torque: 121,700 ft. lbs.

Hammer and Steel Inc.

Description

The Patriot P1, featuring our cutting-edge DrillPro technology refined through extensive field testing and customer feedback, represents a new pinnacle in hydraulic drill design. Engineered for enhanced efficiency and expanded capacity, this drill mitigates common mechanical issues while automating drilling processes for seamless operation. With its larger, interlocking Kelly Bars, it effortlessly tackles even the most challenging soil conditions. The Patriot P1 is empowered by the optional sectional mast, which enables swift configuration changes, granting it the versatility to drill depths ranging from 35′ to 70′. Powered by a robust Cat C4.4 188HP Diesel Engine, delivering maximum torque of 50,000 ft/lbs, it stands as a testament to performance and adaptability. Furthermore, its road legality across all 50 states cements its position as the ultimate choice for a wide spectrum of applications.